Toishi (or Sharpening stone) works

― Sharpening stone Power―

Adopting the Vitrified

Method for performance

1.Stirring

2.High temperature and high pressure pressing

3.Firing

4.Completion

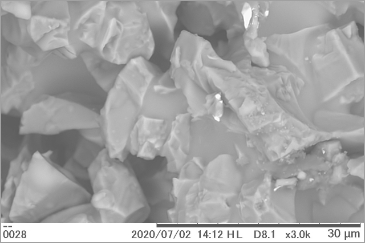

Polished surface with 400 grid size

Polished surface with 1200 grid size

■Electron microscope image (Aoi 1200)

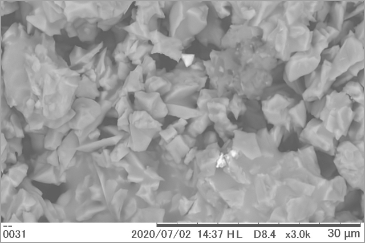

Polished surface with 3000 grid size

■Electron Microscope Image (Shoki 3000)

What's the difference if it's sharpening stones by vitrified method ?

Resistant to water

High performance even in extremely cold and hot climates

Can be used with chemicals (acid and alkali resistant)

Can be used for a long time without deterioration over time

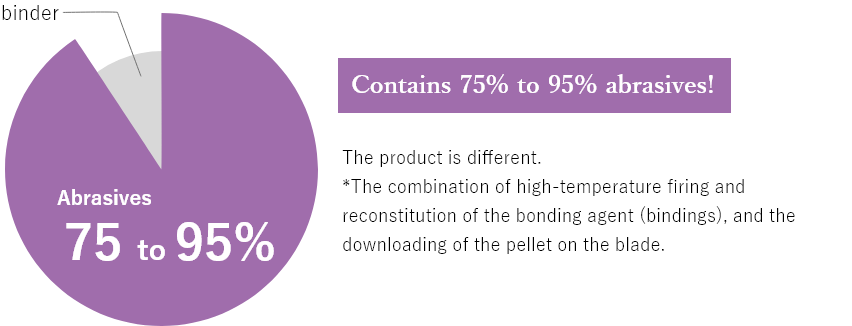

Miyakoshi's sharpening stones have a high ratio of abrasives.

This is why more than 75% of the abrasive grains directly contact the blade.

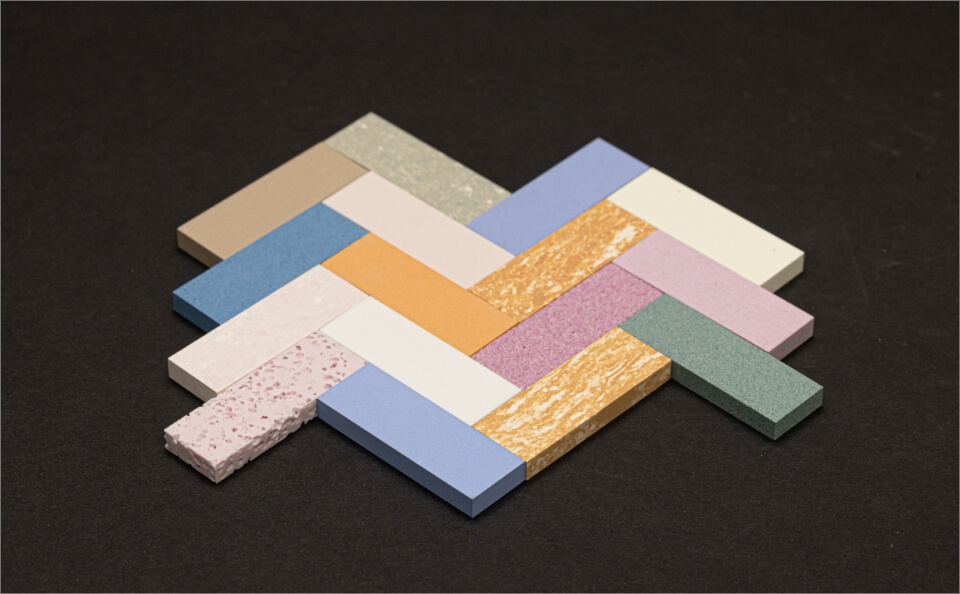

Sharpening stones

Miyakoshi's Sharpening stones

Manufactured using the vitrified method

Sharpening stonemade by resinoid method

Resin-based

Sharpening stone made by magnesia method

Cement-based

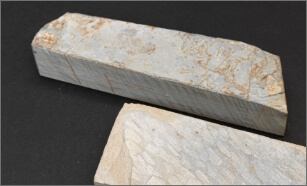

Natural sharpening stone

(mined from the sharpening stone layer)

Uchigumori, Suita

Tozen (a plane finished with a large abrasive stone)

Diamond sharpening stone

We can make the sharpening stone of your choice!

Miyakoshi Seito has been manufacturing grinding wheels with excellent abrasive power since the beginning of the company, incorporating the voices of our customers.

Please feel free to ask us about industrial grinding wheels, etc., which can be made to your desired hardness size with abrasive grains of #46-#6000.

Click here to contact us.

FAQ

View more

Connect

Recruit

We are currently looking for people who

love manufacturing to work with us.

宮越製砥株式会社

Miyagoshi Seito Ltd.

〒601-8045

京都府京都市南区東九条西明田町26番地

26 Nishi Akidacho, Higashikujyo,, Minami-ku, Kyoto-shi, Kyoto〒601-8045

TEL:

075-691-8296

FAX:075-691-3536

© 2021 Miyakoshi Seito Ltd.