FAQ

Frequently asked questions are listed here.

If you have any questions, please feel free to contact us using the contact form.

About Sharpening stone

Q

Do I need a sharpening stone in the first place?

A

This is necessary for the comfortable use of knives, planes, scissors, and other tools.

Q

Do I need a sharpening stone in the first place?

A

It depends on the age, strength, and preference of the user.

Please refer to the chart to make your selection.

How to choose a grinding stone

When a tooth is rusted or chipped

Rouran 220

Rough stone

When it doesn't cut or doesn't cut well

Ajisai 1200

Medium stone

When you want to finish the blade more beautifully.

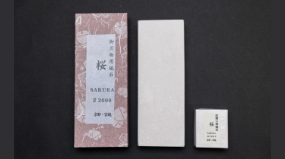

Sakura 2000

Finishing stone

Q

What is the vitrified method?

A

In this method, an abrasive is mixed with a ceramic binder, pressed under high pressure, and then fired at a high temperature (less than 1300°C).

Q

How is it different from sharpening stones made by other methods?

A

The most important difference is its high abrasive power.

Also, because it is fired at high temperature, it can be used safely for cleaning things like knives that handle raw food. There is also a big difference in the fact that it is easy to handle and does not deteriorate even if it is left in water, under the hot sun, in cold weather, or when it is exposed to chemicals.

Q

Why is the polishing power higher?

A

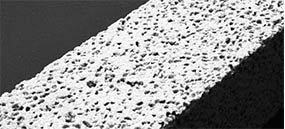

By firing at high temperature, the binder melts and forms a porous structure, allowing the abrasive grains to directly contact the blade.

Image

Q

The sharpening stone seems rougher than other companies' products, why?

A

Sharpening stones made by the resinoid and magnesia methods are not fired at high temperatures, so not only the abrasive but also the binder comes in contact with the blade.

Therefore, the binder also comes in contact with the blade along with the abrasive grains.

Our products may seem rough because all the parts that touch the blade are abrasive grains.

However, our products are made using abrasives with the same grain size as indicated on the label, so you can use them with confidence.

See the scratches on the blade sharpened with a sharpening stone.

Q

How should I sharpen it?

A

There is no specific amount of sharpening that you should do.

It depends on the condition of the blade, so it is best to sharpen it while checking whether it is sharp or not.

For those who are sharpening for the first time, it’s sometimes recommend painting the edge of the blade with an oil-based pen before sharpening. This is because when the painted area disappears, it is a good indication that the blade is being sharpened.

Q

I don't know how much sharpening I should do.

A

There is no specific amount of sharpening that you should do.

It depends on the condition of the blade, so it is best to sharpen it while checking whether it is sharp or not.

For those who are sharpening for the first time, it’s sometimes recommend painting the edge of the blade with an oil-based pen before sharpening. This is because when the painted area disappears, it is a good indication that the blade is being sharpened.

Q

Why do you dip it in water?

A

By dipping the sharpening stone in water, water is contained in the pores of the sharpening stone, which acts as a lubricant when sharpening.

It is recommended that you use the sharpening stone as if you are sharpening it in grit, with sufficient water in it.

Also, since it is made by the vitrified method, it can be used in water.

Q

How do you use the co-grinding sharpening stone?

A

The co-grinding sharpening stone plays an auxiliary role in improving the performance of the main body of the sharpening stone. By simply rubbing the main grinding wheel with a small grinding wheel moistened with water a few times, you can get a good grip on the wheel and improve the grinding performance.

In addition, the abrasive residue left on the surface of the wheel after use is a mixture of fine iron and muddy abrasives, which will interfere with the next grinding if left unattended.

If left unattended, they will interfere with the next round of grinding. It is recommended to thoroughly scrub the surface with a co-grinding wheel after use and wash it with water, so that you can always enjoy comfortable grinding.

Q

About sharpening stones made by the vitrified method

A

There is a slight difference in size due to the high temperature firing process. In order to emphasize the performance of the product, the weight of the molding is increased as much as possible. As a result, brownish color may appear on the side of the sharpening stone, but this is not a problem at all.

Although we do our best to inspect the product, cracks may occur due to the nature of pottery.

We use the same manufacturing method as for tableware, so it is unlikely that cracks will break immediately, but please let us know if there are any inconveniences.

About Purchasing Products

Q

Can I make a payment at a convenience store or by credit card?

A

We are sorry. Currently, we only accept payment by Yamato cash on delivery.

Q

How much does it cost for shipping?

A

1,100yen (tax included) as shipping cost including cash on delivery fee.

If you are located in Hokkaido, Okinawa, or remote islands, you will be charged 1,650yen (tax included) for shipping and handling.

Free shipping will be provided for purchases over 33,000yen (tax included).

For Corporations

Q

Can I place an individual order?

A

Of course you can.

We will try to meet your request for grain size, hardness, and size.

Q

Can it be processed?

A

We can process a variety of shapes (e.g., trapezoidal, comb-shaped, curved, doughnut-shaped, cylindrical, triangular, etc.). However, if you want to process it into a size that the processor does not have, you will have to pay for the cutting diamond separately.

Q

Can you give me an individual quote?

A

Yes. Please inform us with the type, particle size, hardness, size and number of stones.

The price is subject to change for the 4 conditions mentioned above.

Q

Is it possible to produce any kind of product?

A

Depending on the raw material, particle size, hardness, size, processing form, etc., there are some items that cannot be manufactured.

We would appreciate it if you could contact us once.

Q

Can you provide the product in the form of OEM?

A

Yes, we are happy to discuss this with you.

Other

Q

Can you ship to overseas?

A

Various fees and charges will be borne by the customer, but can be handled. Please consult with us.

Recruit

We are currently looking for people who

love manufacturing to work with us.

宮越製砥株式会社

Miyagoshi Seito Ltd.

〒601-8045

京都府京都市南区東九条西明田町26番地

26 Nishi Akidacho, Higashikujyo,, Minami-ku, Kyoto-shi, Kyoto〒601-8045

TEL:

075-691-8296

FAX:075-691-3536

© 2021 Miyakoshi Seito Ltd.